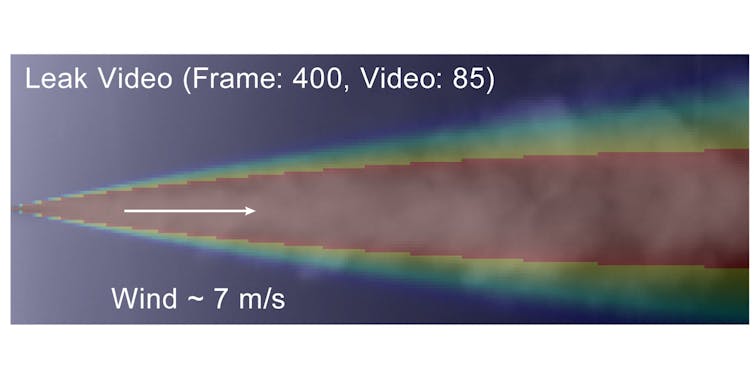

We developed a model to predict whether the camera will detect a leak of given size under different measurement conditions. In order to verify that this model is accurate, we intentionally released methane and compared the corresponding camera images with model results.

We found that the cameras’ effectiveness in detecting leaks was highly variable based on weather conditions. Also, the camera operator’s expertise and even properties of the facility, such as its location and gas composition, affected the readings. Under ideal conditions, the cameras detected over 80 percent of the total leakage at the facility.

But such a high success rate is possible if and only if the camera is operated during periods of low wind, warm weather, clear skies and leaks are imaged from distances of about 30 feet. Under nonideal conditions (high wind, cold days or viewing distance greater than 100 feet), they detected as little as 10 percent of the total leakage.

Recent EPA regulations do not specify many crucial parameters. For example, an operator decides maximum viewing distance and acceptable wind conditions for testing leaks; and there are no requirements on temperature or cloud cover conditions.

With such latitude in determining testing protocols, an operator can perform a leak detection survey, without actually finding any leaks. This can be done by searching for leaks on cold or humid days or measuring from distances farther than about 100 feet. In order to consistently find leaks using this technology, we concluded that EPA’s rules need to be more specific, or use a different metric to track progress.

A possible solution: Fix ‘super-emitters’

“Super-emitters,” as the name implies, are very large leaks with a leak rate between 100 tons/year to over 1,000 tons/year. All tests that have been conducted at gas facilities – production wells, processing facilities and compressor stations – often find a small number of these super-emitters.

Infrared cameras are naturally suited to detect these super-emitters because it is easier to detect bigger leaks than smaller ones, even under unfavorable measurement conditions. Fixing super-emitters could be a cost-effective way for facility operators to significantly reduce leakage and improve safety.

Not all locations are created equal

The number and sizes of leaks at any facility vary significantly across the country. For example, recent research at production facilities has shown that super-emitters contribute to a larger fraction of total leakage in Pennsylvania compared to Texas. Because super-emitters are easily detected by these cameras, leak detection will be more effective in Pennsylvania than in Texas.

In addition to its size, the composition of a leak can also significantly affect detection. Drilled wells can often release nonmethane gases like ethane and propane. Often termed “wet-gas,” these nonmethane compounds are more sensitive to infrared light than methane. Therefore, a leak rich in these compounds will “look” brighter than a similar leak that contains only methane. Such situations commonly occur in regions where significant oil is also extracted along with gas.

These subtleties have important consequences for policy. A camera’s effectiveness depends not only on its own properties, but also on the properties of the facility being tested. An 80 percent success rate in one location will not translate into a similar success rate at other locations.

Source : theconversation.com